Do you have a check engine light on in your car that won’t go away? If so, you may be dealing with the dreaded Cam Position Sensor (CPS) problem. The CPS is responsible for accurate monitoring and reading the position of the camshaft relative to engine rotation, which means it’s critical for proper engine performance.

Without it functioning correctly, problems can range from something as simple as poor idle quality all the way up to catastrophic failure if left unchecked for too long. Here, we’ll explore how to check cam position sensor using basic tools and techniques so your vehicle will run smoothly again!

If you’re having trouble understanding how a cam position sensor works and how to check it for errors, then this blog post is going to provide you with the insight necessary to make an accurate assessment. By reading through this guide, you’ll learn what a cam position sensor actually does and why it can be so important for your engine’s performance.

Additionally, we’ll go over the simple steps needed in order to effectively diagnose if there are any issues with your cam position sensor and determine whether or not repairs need to be made.

Why May You Want to Check Cam Position Sensor?

1. To Prevent Engine Misfires

One of the biggest causes of engine misfires is a malfunctioning cam position sensor. Since the camshaft’s position must be precisely monitored in order for the valves to open and close at the correct time, any disruption in this process can cause issues with your vehicle’s performance.

If your vehicle has been experiencing misfires or rough idle, it may be worth checking the cam position sensor to rule it out as the source of the problem.

2. To Diagnose Problems with Camshaft Timing

If you have noticed a delay in power or reduced acceleration, your cam position sensor may be to blame. This component helps manage engine timing and balance, so any disruption will be noticeable when driving the car.

Checking this part can help diagnose if it is the source of the problem and can help prevent further damage to your engine.

3. To Ensure Proper Performance

A cam position sensor is designed to provide accurate readings of a vehicle’s camshaft so that your engine runs properly. This component requires regular maintenance in order for it to remain functional, and its readings should be regularly checked as part of any routine maintenance.

By ensuring that your sensor is in good working condition, it can help you avoid future issues with your engine and maintain its performance.

Checking the cam position sensor is a relatively simple process that requires basic tools such as a multimeter or an oscilloscope. The exact steps may vary depending on the make and model of the car, but the general idea should remain the same.

How to Check Cam Position Sensor in 5 Easy Steps

Step 1: Gather All The Tools You Will Need

The very first step is to gather all the tools you will need for this job. This includes an adjustable wrench, a digital multimeter, and a flashlight.

Step 2: Locate The Cam Position Sensor

The cam position sensor is typically located near the timing belt or chain of your engine. It has two wires going to it from the ECU (Engine Control Unit). Make sure you can easily access it. Also, use a flashlight to double-check that you have the correct component.

Step 3: Disconnect The Cam Position Sensor

Once you have located the cam position sensor, use an adjustable wrench to disconnect it from its wires. Make sure all connections are safely disconnected before moving onto the next step. Make sure to keep track of where each wire went for easy reattachment after testing.

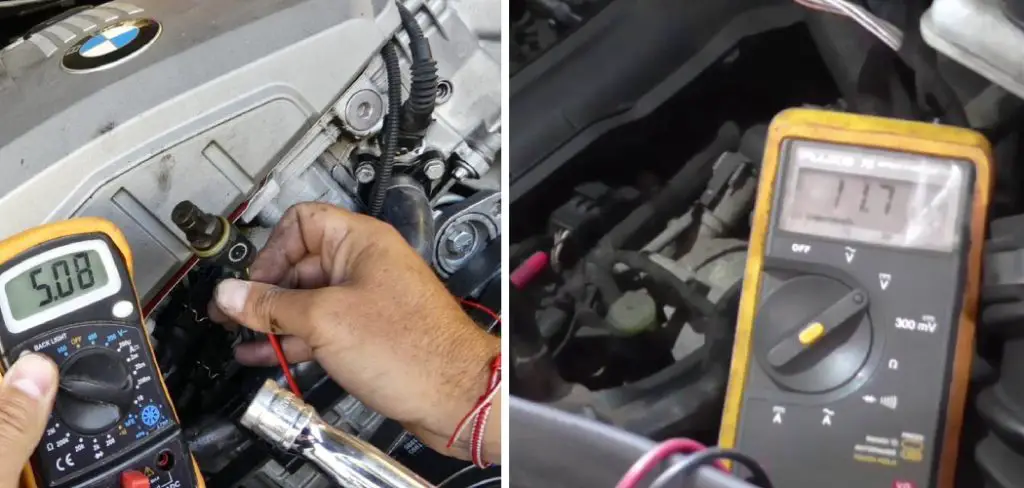

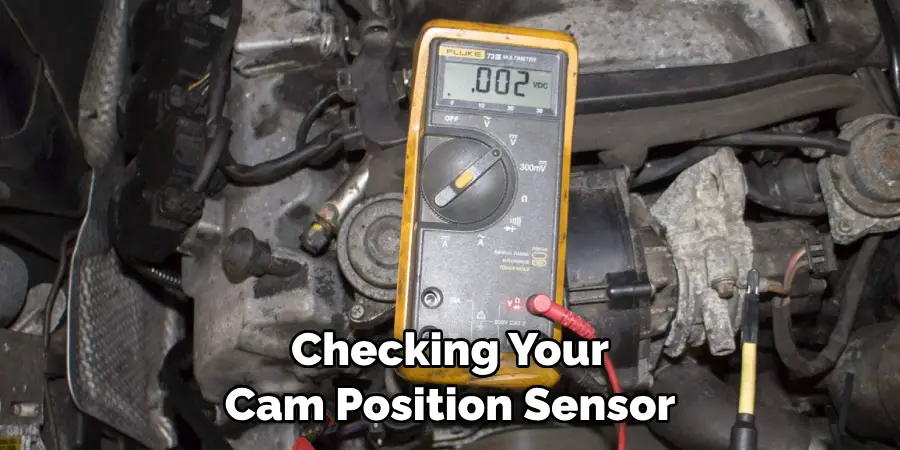

Step 4: Test The Cam Position Sensor With A Multimeter

Now, use a multimeter to test the cam position sensor. Attach one lead of the multimeter to the signal wire and touch the other lead to the ground. Observe the readings on your multimeter. If there is a steady signal, then the cam position sensor is in working condition.

Step 5: Reinstall The Cam Position Sensor

Once you have confirmed that the cam position sensor is in working condition, reinstall it using an adjustable wrench. Make sure to tightly secure all connections and double-check for any loose wires.

Now that you know how to check a cam position sensor, you can confidently troubleshoot any issues with your engine’s timing system. In addition, regular maintenance of the cam position sensor will help ensure that your vehicle runs smoothly and efficiently for many years to come.

Some Extra Tips to Check Cam Position Sensor

1. Do Not Overlook the Obvious

If your engine is running rough, do not blame it on the cam position sensor until you have checked the air filter, spark plugs, and fuel pump. Also, ensure that the vehicle has enough oil and is not overheating.

2. Check for Faulty Wiring and Connections

Checking the wiring of the cam position sensor should be done before any other step. Make sure all wires are connected properly to their terminal points, there’s no corrosion in the connectors, and there are no frayed or broken wires.

3. Test the Sensor

To test the sensor, use an ohmmeter or a voltmeter to measure its resistance and output voltage. If there’s any discrepancy in these readings compared to manufacturer specifications, then it should be replaced.

4. Have Your Vehicle Diagnosed by a Professional

If you are having problems with the cam position sensor, it is best to have your vehicle diagnosed by a professional mechanic. They will be able to further diagnose and confirm if the cam position sensor is the cause of the problem.

5. Replace as Necessary

If after diagnosis, you find that the cam position sensor needs to be replaced, make sure to get a genuine replacement part and install it according to the manufacturer’s instructions. Also make sure to keep an eye on the sensor after installation and ensure that it is functioning properly.

6. Perform Regular Maintenance

Regular maintenance is the best way to ensure that your cam position sensor will last for a long time. This includes changing the oil and filter regularly, as well as checking and replacing any worn parts.

Follow these steps when checking your cam position sensor, and you can be sure that any problems related to this component will be identified and addressed effectively. Remember, proper maintenance is key to keeping your vehicle running smoothly. Good luck!

Frequently Asked Questions

What Precautions Should I Take When Checking a Cam Position Sensor?

When checking a cam position sensor, it is important to wear protective eyewear and gloves to protect yourself from any hot surfaces or debris. Additionally, you should make sure the vehicle is properly supported with jacks and jack stands before attempting any type of repair or diagnostic work, as well as disconnecting the negative terminal on the battery.

This will help to ensure that no electrical shorts occur while checking the cam position sensor.

What Indicators Should I Look For When Checking a Cam Position Sensor?

When checking a cam position sensor, you should look for several indicators such as an illuminated check engine light on your dashboard or any other relevant warning lights.

You may also notice rough engine idling, misfiring, stalling or lack of power. In addition, it is important to check for any possible mechanical problems such as loose wiring or a malfunctioning solenoid.

How Can I Test the Cam Position Sensor?

In order to test the cam position sensor, you will need an OBD-II scanner and a voltmeter. Your OBD-II scanner should be used to retrieve any stored trouble codes in your vehicle’s computer that are related to the cam position sensor.

After retrieving any stored codes, you can then use a voltmeter to test the voltage output of the cam position sensor. If the voltage is not within specification as outlined in your vehicle’s service manual, then it is likely that the sensor is faulty and will need to be replaced.

What Type of Damage Can Occur if I Don’t Check My Cam Position Sensor?

If your cam position sensor is not checked regularly, it can cause serious damage to other components in your vehicle such as the fuel injectors or spark plugs.

Additionally, a faulty cam position sensor may also lead to reduced fuel efficiency and increased emissions. It is important to check your cam position sensor regularly in order to keep your vehicle running smoothly and efficiently.

What Can I Do if My Cam Position Sensor Needs to Be Replaced?

If you find that your cam position sensor needs to be replaced, it is important that you have the job done by a qualified mechanic or professional. This is because the cam position sensor is an intricate part of your vehicle’s engine, and replacing it requires precise measurements and skill.

A qualified mechanic or professional will be able to make sure that the replacement process is done correctly and efficiently.

How Much Does It Cost to Replace a Cam Position Sensor?

The cost of replacing a cam position sensor will vary depending on the make and model of your vehicle, as well as the labor costs associated with the job. Generally speaking, you can expect to pay between $100-$400 for parts and labor when having your cam position sensor replaced.

What Happens if I Don’t Replace a Faulty Cam Position Sensor?

If you do not replace a faulty cam position sensor, it can cause more serious damage to your vehicle in the long run. This is because the cam position sensor plays an important role in regulating engine combustion and timing, and a malfunctioning sensor can lead to reduced fuel efficiency and increased emissions.

Ultimately, checking your cam position sensor regularly can help you avoid costly repairs or replacements in the future. Paying attention to any warning lights or indicators when it comes to your cam position sensor can help you catch any potential problems before they become serious issues.

If you think there might be an issue with your cam position sensor, make sure to have it checked as soon as possible in order to keep your vehicle running smoothly and efficiently.

Conclusion

In conclusion, if you think your car’s cam position sensor is failing, there are a few steps you can take to combat the issue. First, it’s important that you use OBD-II code readers and diagnostic software to check for any codes indicating a problem.

Secondly, make sure to use an appropriate multimeter to complete wiring checks and check the connector pins for corrosion or damage.

Finally, physically inspecting the cam position sensor itself may be required in more complex cases. With these tips in mind, however, you should now have a clearer idea of how to check cam position sensor– no matter what type of engine it has!